Products & services: Tubular heat exchangers

We design and deliver optimised tubular heat exchangers (THE) for a wide range of different areas of applications and combinations of mixtures. We particularly focus on achieving a vibration-free design.

Additional Pictures:

Heat exchangers for biogas plants, biogas treatment.

Improving efficiency, saving on operating costs.

THE for a wide range of different applications and media.

PHE of various designs.

Air-charged heat exchangers, air coolers, air heaters, gas heaters.

Optimised new design and recalculation of heat exchangers.

Make the most of savings potential by optimising whole model series.

Spare parts, repairs, service: fast, competent, worldwide.

Seminars, training, consultation

Seminars and consultation for HE design, inc. optimisation.

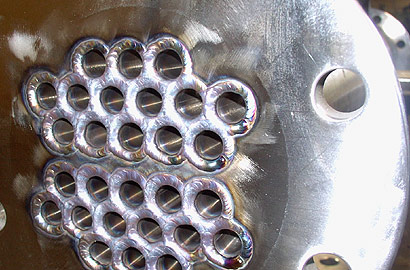

Tubes bundle welded into tube plate

The following tubular heat exchangers (THE), sturdy and proven in industrial practice, are included in our range:

Types

- THE with fixed tube bundle

(without/with sheath compensator) - THE with extractable tube bundle

- Smooth tube bundles

- Ribbed tube bundles

- Bimetal tube bundles

(e.g. inner tube: 1.4571 stainless steel,

outer tube: copper or aluminium) - U-tube HE

- Floating head HE

- HE with stuffing box seal

- Vertical or horizontal design

- Safety HE (double tube)

- Double tube HE

- Compact lamella-tube HE

- Cross-twist tube and twist tube bundle

- Further high-performance bundles

(tornado flow, micro-fine, inner star etc.)

All the tubular heat exchangers we deliver are specially protected against vibration (vibration-free design)!

Technical data (approx.)

- Temperature: -50 to +900°C

- Pressure: Vacuum up to >500 barg

- Heat capacity: 1 kW to >20,000 kW

Material

- Standard versions:

Stainless steel (1.4571/316Ti, 1.4541/321, 1.4301/304 etc.),

steel, copper, brass, CuNi10Fe etc. - Special versions:

1.4462/Duplex, 1.4404/316L (e.g. Ra<=0.8µm),

1.4539/904L, 1.4828, titanium, monel, tantalum, nickel-based alloys etc.

Application possibilities

- Biogas treatment, energy technology, energy efficiency, heat recovery, waste gas technology, marine applications, chemical industry, power station engineering, oil technology, pressure gas technology, drying technology, compressed air technology etc.

Examples

- Biogas/water-glycol cooler, biomethane/water cooler, waste gas/air HE, compressed air/water HE, ultrapure water/water HE, steam/gas, gas/gas HE, air/air HE etc.