Your independent partner for industrial heat exchangers

We are a young expanding company specialising in the delivery and design of industrial heat exchangers (HE).

Renewable energies

Energy saving

Tubular heat exchangers

Plate heat exchangers

Air-charged heat exchangers

Recalculation & optimisation

We have consciously focused on the future-oriented markets of renewable energies and energy-saving. What makes us different from other heat exchanger companies is mainly:

- Our independence

- The use of optimised heat-exchange techniques

Our independence allows us to offer and supply our customers the optimum heat exchanger for their respective application from a whole series of brands, whereby we only use products from experienced and tested manufacturing companies.

At the same time, our use of innovative heat-exchange technologies results in a further advantage for our customers: Highly efficient heat exchangers, the size of which has been reduced by up to 50% and more, with a first-class cost-performance ratio and very short lead times.

All our manufacturing partners have the standard certification e.g. in compliance with the Pressure Equipment Directive 97/23/EC, AD 2000, ASME VIII Div. 1, or in compliance with the respective regulations of the different classification societies.

We work in the following areas:

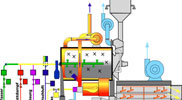

Renewable energies (biogas technology)

Biogas plants and biogas treatment plants (biogas purification) are an important area of application for our heat exchangers. In the field of renewable energies are optimised in terms of thermal design and have been matched to the respective operating data. We can even calculate complex thermo-dynamic processes such as mixture evaporation or other two-phase flows absolutely exactly.

Energy saving (energy efficiency, heat recovery, cost reduction)

Energy saving is one important way a company can increase its competitive situation. Use of our heat exchangers increases the efficiency of machines and plant, for example, thus reducing operating costs. This results in significant advantages for plant manufacturers, operators and the environment.

Design and recalculation, optimisation

We design new heat exchangers as well as recalculating (revision or comparison calculation) heat exchanger performance. In the case of new designs, we take all your process-related and structural requirements into consideration (general conditions). We set great store by an optimised design, both with regard to the best possible heat transfer and minimum vibration.

Tubular heat exchangers

We deliver tubular heat exchangers with diameters of between 76 mm and 2,500 mm and lengths of up to 10 m for use in a wide range of different applications. Tube types, design and materials are optimised to match your requirements. Tubes with outer ribs or turbulators fitted in them e.g. using a cross-helix structure, often lead to significant advantages in terms of both structure and price.

Plate heat exchangers

We calculate and deliver plate heat exchangers in the dimensions you require for various areas of application, e.g. bio-energy, fluid engineering, drying technology. The sizes range from 100 mm to more than 3,000 mm plate height, with capacity data from 1 kW to 400,000 kW. The plates are manufactured using special multi-span embossing technology, allowing maximum alpha values and k values to be created, resulting in a compact, favourably priced HE.

Air-cooled (air-charged) heat exchangers

Our air-charged heat exchangers are designed and optimised according to your requirements. Turbo lamellae can often be used downstream, which improves the alpha value (heat transfer coefficient), allowing surface area and thus cost to be saved. Depending on the area of application, we calculate the heat exchangers as coolers or heaters (air heaters, gas heaters). Our product range includes table coolers, coolers, register coolers as well as air heaters, gas heaters etc.